PTC Creo Parametric – Advance Course Modules

PTC Creo Parametric – Advance Course Modules, available at $54.99, has an average rating of 4.64, with 189 lectures, based on 139 reviews, and has 845 subscribers.

You will learn about Learn the Design process i.e., Modelling, Assembling and Drafting Learn all the significant technical tools in Sheet-Metal Modelling Learn to prepare Assembly of the Industrial components, Learn to Prepare Technical Drawing of the Modelled geometries Learn to create your own Drawing Sheet Format and Template This course is ideal for individuals who are Students pursuing Mechanical , Aerospace, Ship, Automobile and other technical courses such as designing/production/manufactoring etc or Any Student who like to enhance their technical skills of conventional part modelling to advanced level geometrical modelling, assembly, and drafting or Students who learnt Creo Parametric Part modelling and wish to extend their knowledge on other modules of Creo or Graduates who like to add a skill in their resume or Working professionals who wish to enlighten their knowledge of Sheetmetal, Assembly and Drafting It is particularly useful for Students pursuing Mechanical , Aerospace, Ship, Automobile and other technical courses such as designing/production/manufactoring etc or Any Student who like to enhance their technical skills of conventional part modelling to advanced level geometrical modelling, assembly, and drafting or Students who learnt Creo Parametric Part modelling and wish to extend their knowledge on other modules of Creo or Graduates who like to add a skill in their resume or Working professionals who wish to enlighten their knowledge of Sheetmetal, Assembly and Drafting.

Enroll now: PTC Creo Parametric – Advance Course Modules

Summary

Title: PTC Creo Parametric – Advance Course Modules

Price: $54.99

Average Rating: 4.64

Number of Lectures: 189

Number of Published Lectures: 189

Number of Curriculum Items: 189

Number of Published Curriculum Objects: 189

Original Price: $109.99

Quality Status: approved

Status: Live

What You Will Learn

- Learn the Design process i.e., Modelling, Assembling and Drafting

- Learn all the significant technical tools in Sheet-Metal Modelling

- Learn to prepare Assembly of the Industrial components,

- Learn to Prepare Technical Drawing of the Modelled geometries

- Learn to create your own Drawing Sheet Format and Template

Who Should Attend

- Students pursuing Mechanical , Aerospace, Ship, Automobile and other technical courses such as designing/production/manufactoring etc

- Any Student who like to enhance their technical skills of conventional part modelling to advanced level geometrical modelling, assembly, and drafting

- Students who learnt Creo Parametric Part modelling and wish to extend their knowledge on other modules of Creo

- Graduates who like to add a skill in their resume

- Working professionals who wish to enlighten their knowledge of Sheetmetal, Assembly and Drafting

Target Audiences

- Students pursuing Mechanical , Aerospace, Ship, Automobile and other technical courses such as designing/production/manufactoring etc

- Any Student who like to enhance their technical skills of conventional part modelling to advanced level geometrical modelling, assembly, and drafting

- Students who learnt Creo Parametric Part modelling and wish to extend their knowledge on other modules of Creo

- Graduates who like to add a skill in their resume

- Working professionals who wish to enlighten their knowledge of Sheetmetal, Assembly and Drafting

The objective of this course is to enhance your product designing skills.

The curriculum is especially oriented to make you understand the concepts with ease, and reduce your fear to work with the complicated tools of product designing.

The course offers you hours and hours of HD content that can be accessed from your mobile/laptop/desktop.

Sign up now, and accessthe world’s best course on Sheet-Metal, Assembly and Drafting using CREO PARAMETRIC.

Through the course, you will be familiarized will the following significant tools:

Sheet Metal

· Introduction to various Sheet-metal concepts

· Creating Primary and Secondary Walls using different tool such as Planar, Flat, Flange, Extrude.

· Types of Walls

· Reliefs, Its necessity, & types.

· Corner reliefs, Corner Treatment, Mitre-cuts.

· Bending Sheet metal in Creo

· Tools used to bend sheet metal.

· Types of bend

· Edge & Planar Bend

· Unbending Sheet metal in Creo

· Different types of unbending options

· Cut-outs in Sheet-metal

· Forms, and its types – Punch, Die, Sketch and Quilt

· Rips, and its types – Edge, Sketch, Surface, and Rip Connect

Assembly

· Bottom-up and Top-Down Approach

· Different constraints in Assembly (Coincident, Distance, Normal, Parallel, Angle offset etc.,)

· Global Interference

· Repeat components

· Create Exploded View in Assembly.

· Add Sub-Assembly in Assembly.

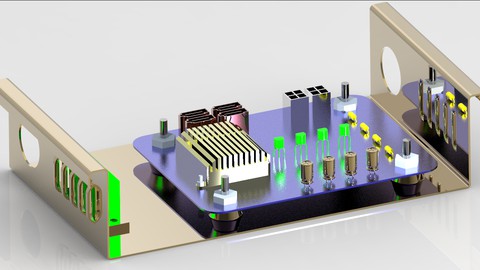

· Detailed design process, i.e., from Part Modelling to Assembly of industrial components namely, “Butterfly Valve, Pedestal bearing and Electrical Cabinet Assembly)

Creo Drawing

· Elements of a Drawing Sheet

· Creation of a Drawing Format (User defined)

· Adding parameters to drawing sheets.

· Create user-defined parameters in title block

· Basic dimensioning

· Lines and line styles used in Dimensioning

· Create Detailed view in drawing sheet

· Visible Area View

· Create Auxiliary View

· Create Revolved View

· Create cross-sectional view of a part model in drawing sheet

· Create cross-sectional view of an assembly in drawing sheet

· Create Local View

· Create Offset View

· Create Exploded view in Drawing sheet

· Creating our own Detailed File.

· Adjusting dimensions using different tools

· Adding tolerances to the dimensions

· Adding Notes in the drawing sheets

· Adding Ordinate Dimensions.

· Adding Surface Finish Symbols

· Preparing Report Table: Bill of Materials (BOM)

· Creating Balloons on the Exploded view

· Create a user-defined template in Creo

Model Based Definitions

– Combo Views

– Annotations in Combo Views

– Driving and Driven Dimensions

– Different References for creating Annotations

The course doesn’t not require you to have any prerequisites.

By understanding the conceptual parameters, you can work on your own to explore and prepare your imagination into a virtual 3-D model.

I am looking forward to Teaching you all About the PTC CREO PARAMETRIC

Course Curriculum

Chapter 1: Introduction

Lecture 1: Introduction

Lecture 2: Join the community

Chapter 2: Sheet Metal -Theory

Lecture 1: Article

Lecture 2: Introduction to Sheet-Metal

Lecture 3: What are the various Sheet-Metal operations – Bending

Lecture 4: Sheet-Metal operations : Shearing, Blanking and Punching operations

Lecture 5: Sheet-Metal operations: Trimming, Coining, Nothcing etc.,

Lecture 6: Sheet-Metal Operations: Forming

Lecture 7: Various materials used in Sheet-Metal

Lecture 8: Sheet Metal Hand-tools

Lecture 9: What is Hem and Seam?

Chapter 3: Sheet-Metal in Creo Parametric : FLAT, FLANGE & RELIEF

Lecture 1: Opening the Sheet-Metal module in Creo Parametric

Lecture 2: Mouse controls in Sheet Metal

Lecture 3: Create a Primary Wall using Extrude

Lecture 4: Create a Primary Wall using Planar

Lecture 5: Other tools to create a Primary Wall

Lecture 6: Create a Secondary Wall using FLAT

Lecture 7: FLAT wall from the side-veiw

Lecture 8: Create a Secondary Wall using FLANGE

Lecture 9: Create a Secondary Wall using EXTRUDE

Lecture 10: Secondary Wall Thickness

Lecture 11: Different Bend Position

Lecture 12: Introduction to Relief

Lecture 13: Necessity of Relief and Types of Relief : Rip and Rectangular

Lecture 14: Types of Relief : Obround

Lecture 15: Corner Reliefs

Lecture 16: Corner Treatment

Lecture 17: Mitre Cuts

Lecture 18: Types of Flat Walls – 1

Lecture 19: Types of Flat Wall -2

Lecture 20: Types of Flange Wall

Lecture 21: Chain Ends on Walls

Lecture 22: Excercise

Chapter 4: Bends in Creo Parametric

Lecture 1: Introduction to Bend

Lecture 2: Bend using Dynamic Bend Line

Lecture 3: Bend on a Bent Surface

Lecture 4: Features in Bend Command

Lecture 5: Roll Bend

Lecture 6: Vertical Roll Bend

Lecture 7: Bend on the other side

Lecture 8: Bend Transition – Single

Lecture 9: Double Transitions in Bend

Lecture 10: Bend Reliefs

Lecture 11: Edge Bend

Lecture 12: Edge Bend – 2

Lecture 13: Edge Bend reliefs

Lecture 14: Planar Bend

Lecture 15: Planar Bend – Roll Type

Lecture 16: Unbend sheetmetal

Lecture 17: Manual Unbending

Lecture 18: Cross-section driven unbend

Lecture 19: Converting Part Model into Sheet Metal- using Shell

Lecture 20: Unbend the Sheetmetal imported from part model

Lecture 21: Different deformation controls in Unbend

Lecture 22: Distinct Areas-Unbend – Conversion of Part to Sheet metal using Driving surface

Lecture 23: Distinct Areas in Sheet metal

Lecture 24: Split Areas

Lecture 25: Distinct Areas – Unbend

Chapter 5: Cut-Outs in Sheet Metal

Lecture 1: Extrude Cut-Out

Lecture 2: Driving Surface and Offset Surface

Lecture 3: Types of Cut-Outs

Lecture 4: Thin Sheet Cutout

Chapter 6: Forms in Sheet Metal

Lecture 1: Introduction to Punch Form

Lecture 2: Flipping options in Punch Form

Lecture 3: Different Placement options

Lecture 4: Create a pattern with a Form

Lecture 5: Create a Punch using Part module

Lecture 6: Do it yourself! Practice

Lecture 7: Solution: Do it yourself! (previous video)

Lecture 8: Solution-Step-by-Step

Lecture 9: Flatten Form

Lecture 10: Sketch Form

Lecture 11: Die Form-1

Lecture 12: Options in Die Form

Lecture 13: Quilt Form

Lecture 14: Quilt Form – Additional options

Lecture 15: Twist a Sheet-Metal

Lecture 16: Twist – Excercise-1

Lecture 17: Excercise – 2

Chapter 7: Rips in Sheet metal

Lecture 1: Edge Rip

Lecture 2: Sketch Rip

Lecture 3: Surface Rip

Lecture 4: Rip Connect

Chapter 8: Assembling in Creo

Lecture 1: Introduction to Assembly

Lecture 2: Import a part model in Assembly

Lecture 3: Constraints in Assembly

Lecture 4: Constraints in Assembly contd.,

Lecture 5: Learn Assembly with Butterfly Valve – Main body

Lecture 6: Butterfly valve – Shaft – Global Interferences

Lecture 7: Butterfly Valve – Disk – Show component in separate window

Lecture 8: Butterfly Valve : Plate and Bolt – Repeat option

Lecture 9: Butterfly Valve – Bolt on the disk – Repeat

Instructors

-

Mohammed Khan

Engineer

Rating Distribution

- 1 stars: 2 votes

- 2 stars: 4 votes

- 3 stars: 10 votes

- 4 stars: 47 votes

- 5 stars: 76 votes

Frequently Asked Questions

How long do I have access to the course materials?

You can view and review the lecture materials indefinitely, like an on-demand channel.

Can I take my courses with me wherever I go?

Definitely! If you have an internet connection, courses on Udemy are available on any device at any time. If you don’t have an internet connection, some instructors also let their students download course lectures. That’s up to the instructor though, so make sure you get on their good side!

You may also like

- Top 10 Language Learning Courses to Learn in November 2024

- Top 10 Video Editing Courses to Learn in November 2024

- Top 10 Music Production Courses to Learn in November 2024

- Top 10 Animation Courses to Learn in November 2024

- Top 10 Digital Illustration Courses to Learn in November 2024

- Top 10 Renewable Energy Courses to Learn in November 2024

- Top 10 Sustainable Living Courses to Learn in November 2024

- Top 10 Ethical AI Courses to Learn in November 2024

- Top 10 Cybersecurity Fundamentals Courses to Learn in November 2024

- Top 10 Smart Home Technology Courses to Learn in November 2024

- Top 10 Holistic Health Courses to Learn in November 2024

- Top 10 Nutrition And Diet Planning Courses to Learn in November 2024

- Top 10 Yoga Instruction Courses to Learn in November 2024

- Top 10 Stress Management Courses to Learn in November 2024

- Top 10 Mindfulness Meditation Courses to Learn in November 2024

- Top 10 Life Coaching Courses to Learn in November 2024

- Top 10 Career Development Courses to Learn in November 2024

- Top 10 Relationship Building Courses to Learn in November 2024

- Top 10 Parenting Skills Courses to Learn in November 2024

- Top 10 Home Improvement Courses to Learn in November 2024