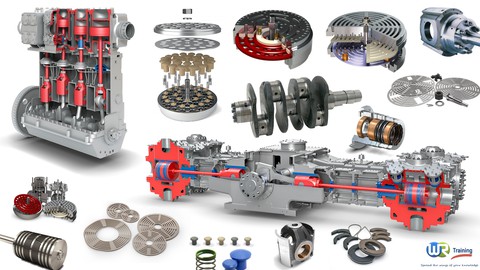

Reciprocating Compressors : Principles , Operation & Design

Reciprocating Compressors : Principles , Operation & Design, available at $74.99, has an average rating of 4.4, with 101 lectures, 1 quizzes, based on 222 reviews, and has 1418 subscribers.

You will learn about Understand the working principles of reciprocating compressors for a successful operation of your plant and piping system Understand the construction details of reciprocating compressors for a successful maintenance and troubleshooting (crankshafts, bearings, crossheads, connecting rods, pistons, packings, rings, valves, unloaders…) Perform various calculations to size and assess compressor performance (head, discharge temperature, inlet capacity, piston displacement, volumetric efficiency…) Understand what affects the selection and design of reciprocating compressors (process conditions, gas characteristics, foundation needs, power supply, interstaging, altitude…) Know how you can adapt your compressor capacity to your system demand changes using various techniques (intake valve unloading, clearance pocket, variable volume valve, 5 step control…) Understand the concept of pulsation, how it can affect your compressor performance and how to control it according to the API 618 standard Know how to size suction and discharge volume bottles to control reciprocating compressor pulsation Understand the importance of compressor lubrication Discover the various compressor lubrication systems and how they operate (splash, splash and flood, full pressure circulation…) Understand the importance of compressor cooling, intercooling and aftercooling Discover the various compressor cooling systems and how they operate (series flow, parallel flow, closed systems…) Analyze the problems in operation related to compressor valves, pulsation control, capacity control… This course is ideal for individuals who are Mechanical, Process and Chemical Engineers or Product Engineers and Technologists or Operation, Technical Service and Maintenance Professionals or Engineers, Consultants and Sales professionals or Technical professionals responsible for rotating equipment inspection or Technical professionals responsible for interdisciplinary energy projects It is particularly useful for Mechanical, Process and Chemical Engineers or Product Engineers and Technologists or Operation, Technical Service and Maintenance Professionals or Engineers, Consultants and Sales professionals or Technical professionals responsible for rotating equipment inspection or Technical professionals responsible for interdisciplinary energy projects.

Enroll now: Reciprocating Compressors : Principles , Operation & Design

Summary

Title: Reciprocating Compressors : Principles , Operation & Design

Price: $74.99

Average Rating: 4.4

Number of Lectures: 101

Number of Quizzes: 1

Number of Published Lectures: 101

Number of Published Quizzes: 1

Number of Curriculum Items: 102

Number of Published Curriculum Objects: 102

Original Price: €219.99

Quality Status: approved

Status: Live

What You Will Learn

- Understand the working principles of reciprocating compressors for a successful operation of your plant and piping system

- Understand the construction details of reciprocating compressors for a successful maintenance and troubleshooting (crankshafts, bearings, crossheads, connecting rods, pistons, packings, rings, valves, unloaders…)

- Perform various calculations to size and assess compressor performance (head, discharge temperature, inlet capacity, piston displacement, volumetric efficiency…)

- Understand what affects the selection and design of reciprocating compressors (process conditions, gas characteristics, foundation needs, power supply, interstaging, altitude…)

- Know how you can adapt your compressor capacity to your system demand changes using various techniques (intake valve unloading, clearance pocket, variable volume valve, 5 step control…)

- Understand the concept of pulsation, how it can affect your compressor performance and how to control it according to the API 618 standard

- Know how to size suction and discharge volume bottles to control reciprocating compressor pulsation

- Understand the importance of compressor lubrication

- Discover the various compressor lubrication systems and how they operate (splash, splash and flood, full pressure circulation…)

- Understand the importance of compressor cooling, intercooling and aftercooling

- Discover the various compressor cooling systems and how they operate (series flow, parallel flow, closed systems…)

- Analyze the problems in operation related to compressor valves, pulsation control, capacity control…

Who Should Attend

- Mechanical, Process and Chemical Engineers

- Product Engineers and Technologists

- Operation, Technical Service and Maintenance Professionals

- Engineers, Consultants and Sales professionals

- Technical professionals responsible for rotating equipment inspection

- Technical professionals responsible for interdisciplinary energy projects

Target Audiences

- Mechanical, Process and Chemical Engineers

- Product Engineers and Technologists

- Operation, Technical Service and Maintenance Professionals

- Engineers, Consultants and Sales professionals

- Technical professionals responsible for rotating equipment inspection

- Technical professionals responsible for interdisciplinary energy projects

June 24 course update:

We have added new video lectures. In addition, new quizzes are being added to help you test your knowledge and emphasize the key learning points. The quiz will include:

-

True/False questions

-

Multi-choice questions

-

Images, cross-sectionnal views

-

Solved problems

-

and much more…

When you think you’ve got a good grasp on a topic within the course, you can test your knowledge by taking the quiz. If you pass, wonderful ! If not, you can review the videos and notes again or ask us for help in the Q&A section.

—

Reciprocating compressors of various designs and applications are encountered nowadays throughout refining, petrochemical and process industries as well as in power generation and environmental engineering.

This course is designed to provide you with a complete understanding of construction details and functioning of reciprocating compressors. This understanding is a prerequisite for a successful operation of your plant and piping system.

The course includes extensive graphics, 3D animations and cross-sectional viewsto give you a virtual practical exposure on reciprocating compressors.

The objective of this course is threefold :

1.Break down for you all the reciprocating compressor operating principles into easily digestible concepts like gas compression, capacity control, pulsation control, compressor lubrication and cooling…

2. Illustrate through 3D animations and cross-sectional views the main compressor mechanical components, state their function and operating limits, like bearings, packings, crossheads, pistons, valves…

3.Provide guidelines and best practices for operation, maintenance and troubleshooting of reciprocating compressors in accordance with the API 618 standard

So with no further ado, check out the free preview videos and the curriculum of the course and we look forward to seeing you in the first section.

Hope to see you there

WR Training

Spread the wings of your knowledge

Course Curriculum

Chapter 1: ABOUT THE COURSE

Lecture 1: Introduction

Lecture 2: Before you start this course

Chapter 2: COMPRESSORS OVERVIEW

Lecture 1: Compressors overview : Introduction

Lecture 2: Compression methods

Chapter 3: THEORY OF RECIPROCATING COMPRESSORS

Lecture 1: Theory of reciprocating compressors : Introduction

Lecture 2: Reciprocating compressors : Simplified 3D animation

Lecture 3: Pressure – Volume diagram

Lecture 4: Piston displacement

Lecture 5: Volumetric efficiency

Lecture 6: Inlet capacity

Lecture 7: Piston speed

Lecture 8: Discharge temperature

Lecture 9: Compressor head

Lecture 10: Power

Lecture 11: Valve loss

Lecture 12: Clearance loss

Lecture 13: Piston ring leakage

Lecture 14: Valve slip

Lecture 15: Effect of multistaging

Lecture 16: Interstage pressures

Lecture 17: Effect of altitude

Lecture 18: Brake horsepower

Chapter 4: CHARACTERISTICS OF RECIPROCATING COMPRESSORS

Lecture 1: Introduction

Lecture 2: Classifications

Lecture 3: Automatic valves

Lecture 4: Useful terminology

Chapter 5: COMPRESSOR TYPE SELECTIONS

Lecture 1: Considerations in selection

Lecture 2: Selection possibilities

Lecture 3: Selection of AIR compressors

Lecture 4: Selection of PROCESS compressors

Chapter 6: RECIPROCATING vs CENTRIFUGAL

Lecture 1: Reciprocating compressors in a process system

Lecture 2: Centrifugal compressors in a process system

Chapter 7: MECHANICAL DESIGN OF RECIPROCATING COMPRESSORS

Lecture 1: Mechanical design : Introduction

Lecture 2: Crankcase

Lecture 3: Distance piece

Lecture 4: Cylinders

Lecture 5: Cylinder arrangements

Lecture 6: Cylinder materials

Lecture 7: Cylinder liners

Lecture 8: Pistons

Lecture 9: Piston dismantling

Lecture 10: Piston materials

Lecture 11: Piston to piston rod connections

Lecture 12: Piston rods

Lecture 13: Piston rod materials

Lecture 14: Piston rod to crosshead connections

Lecture 15: Crossheads

Lecture 16: Crankshafts

Lecture 17: Crankshaft – Rod – Crosshead – Piston Assembly

Lecture 18: Piston rings and rider bands

Lecture 19: Piston rod packings

Lecture 20: Packing rings

Lecture 21: Packing ring arrangements : Single acting

Lecture 22: Packing ring arrangements : Double acting

Lecture 23: Packing ring arrangements : Pressure breaker

Lecture 24: Piston rod packing assembly

Lecture 25: Oil wiper packing

Chapter 8: COMPRESSOR VALVES

Lecture 1: Compressor valves : Introduction

Lecture 2: What is a compressor valve ?

Lecture 3: Basic requirements

Lecture 4: Basic function

Lecture 5: Valve types

Lecture 6: Ported plate valves

Lecture 7: Ported plate valves – 3D animation

Lecture 8: Concentric ring valves

Lecture 9: Concentric ring valves – 3D animation

Lecture 10: Disc valves (poppet)

Lecture 11: Rectangular valves

Lecture 12: Suitability of valves

Lecture 13: Valve materials

Lecture 14: Valve failure analysis

Lecture 15: Troubleshooting valve problems

Lecture 16: How to install and remove a compressor valve

Chapter 9: PULSATION CONTROL

Lecture 1: Pulsation control

Lecture 2: Sizing a compressor volume bottles

Chapter 10: CAPACITY CONTROL OF RECIPROCATING COMPRESSORS

Lecture 1: Capacity control : Introduction

Lecture 2: Intake valve unloading

Lecture 3: Intake valve unloading – Hand operated valves

Lecture 4: Intake valve unloading – Air operated valves

Lecture 5: 5 step control

Lecture 6: Clearance pocket

Lecture 7: Clearance pocket – Hand operated valve

Lecture 8: Clearance pocket – Air operated valve

Lecture 9: Clearance pocket – Variable volume valve

Lecture 10: Intake valve unloading combined with clearance pocket

Chapter 11: LUBRICATION OF RECIPROCATING COMPRESSORS

Lecture 1: Compressor lubrication : Introduction

Lecture 2: Crankcase / Bearings lubrication methods

Lecture 3: Lubrication Method #1 : Splash lubrication

Lecture 4: Lubrication Method #2 : Splash and flood lubrication

Instructors

-

WR Training

Petroleum Petrochemical & Chemical Engineering

Rating Distribution

- 1 stars: 2 votes

- 2 stars: 4 votes

- 3 stars: 22 votes

- 4 stars: 86 votes

- 5 stars: 108 votes

Frequently Asked Questions

How long do I have access to the course materials?

You can view and review the lecture materials indefinitely, like an on-demand channel.

Can I take my courses with me wherever I go?

Definitely! If you have an internet connection, courses on Udemy are available on any device at any time. If you don’t have an internet connection, some instructors also let their students download course lectures. That’s up to the instructor though, so make sure you get on their good side!

You may also like

- Top 10 Language Learning Courses to Learn in November 2024

- Top 10 Video Editing Courses to Learn in November 2024

- Top 10 Music Production Courses to Learn in November 2024

- Top 10 Animation Courses to Learn in November 2024

- Top 10 Digital Illustration Courses to Learn in November 2024

- Top 10 Renewable Energy Courses to Learn in November 2024

- Top 10 Sustainable Living Courses to Learn in November 2024

- Top 10 Ethical AI Courses to Learn in November 2024

- Top 10 Cybersecurity Fundamentals Courses to Learn in November 2024

- Top 10 Smart Home Technology Courses to Learn in November 2024

- Top 10 Holistic Health Courses to Learn in November 2024

- Top 10 Nutrition And Diet Planning Courses to Learn in November 2024

- Top 10 Yoga Instruction Courses to Learn in November 2024

- Top 10 Stress Management Courses to Learn in November 2024

- Top 10 Mindfulness Meditation Courses to Learn in November 2024

- Top 10 Life Coaching Courses to Learn in November 2024

- Top 10 Career Development Courses to Learn in November 2024

- Top 10 Relationship Building Courses to Learn in November 2024

- Top 10 Parenting Skills Courses to Learn in November 2024

- Top 10 Home Improvement Courses to Learn in November 2024