Valves : Principles , Operation & Designs

Valves : Principles , Operation & Designs, available at $64.99, has an average rating of 4.45, with 147 lectures, 1 quizzes, based on 915 reviews, and has 5581 subscribers.

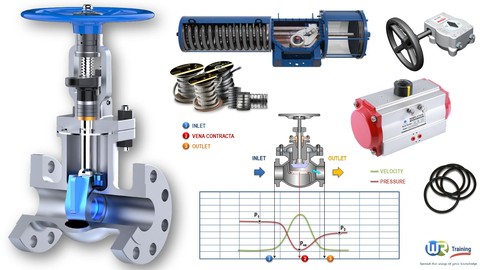

You will learn about Understand valves and control valves working principles for successful operation of your plant and piping systems Understand valve construction details (bonnet, stem, disk, seat, packing, body, etc) Know the characteristics and applications for each valve type (ball, plug, gate, pinch, butterfly, diaphragm, check, needle…) Know how to choose the correct valve for a certain application Know how to dismantle and assemble all types of valves using 3D and 2D models Identify and know the principles of operation of common valve actuators (pneumatic, hydraulic, electrical, etc) Understand how single acting and double acting pneumatic actuators work through graphics and 3D animations Understand the principle of fail open (FO) and fail close (FC) actuators Know how to convert a single acting spring return actuator to a double acting actuator and vice versa Know how to convert a fail close actuator to a fail open actuator and vice versa Learn how to size valves Learn how to calculate the resistance coefficient "K" of any valves Learn what the flow coefficient "Cv" of a control valve means and how to use it in assessing flows and pressure drops Understand the theory of regulating flow with control valves Understand the concepts of cavitation and choking in control valves through graphics and 3D animations Learn how to size and select a control valve when designing and operating any piping system for both gases and liquids Know and identify valve symbols on engineering drawings such as P&ID's Know the standards and conventions for valve status (open, closed, throttled) Identify valve position and failure mode on your P&IDs (LO, LC, FO, FC, FAI…) And much more… This course is ideal for individuals who are Chemical, Process, Petroleum Engineers or Design Engineers or Piping Engineers or Plant Engineers or Facility Managers or Maintenance Technicians or Mechanics or Plant Operators or Recent College Graduates It is particularly useful for Chemical, Process, Petroleum Engineers or Design Engineers or Piping Engineers or Plant Engineers or Facility Managers or Maintenance Technicians or Mechanics or Plant Operators or Recent College Graduates.

Enroll now: Valves : Principles , Operation & Designs

Summary

Title: Valves : Principles , Operation & Designs

Price: $64.99

Average Rating: 4.45

Number of Lectures: 147

Number of Quizzes: 1

Number of Published Lectures: 147

Number of Published Quizzes: 1

Number of Curriculum Items: 148

Number of Published Curriculum Objects: 148

Original Price: €219.99

Quality Status: approved

Status: Live

What You Will Learn

- Understand valves and control valves working principles for successful operation of your plant and piping systems

- Understand valve construction details (bonnet, stem, disk, seat, packing, body, etc)

- Know the characteristics and applications for each valve type (ball, plug, gate, pinch, butterfly, diaphragm, check, needle…)

- Know how to choose the correct valve for a certain application

- Know how to dismantle and assemble all types of valves using 3D and 2D models

- Identify and know the principles of operation of common valve actuators (pneumatic, hydraulic, electrical, etc)

- Understand how single acting and double acting pneumatic actuators work through graphics and 3D animations

- Understand the principle of fail open (FO) and fail close (FC) actuators

- Know how to convert a single acting spring return actuator to a double acting actuator and vice versa

- Know how to convert a fail close actuator to a fail open actuator and vice versa

- Learn how to size valves

- Learn how to calculate the resistance coefficient "K" of any valves

- Learn what the flow coefficient "Cv" of a control valve means and how to use it in assessing flows and pressure drops

- Understand the theory of regulating flow with control valves

- Understand the concepts of cavitation and choking in control valves through graphics and 3D animations

- Learn how to size and select a control valve when designing and operating any piping system for both gases and liquids

- Know and identify valve symbols on engineering drawings such as P&ID's

- Know the standards and conventions for valve status (open, closed, throttled)

- Identify valve position and failure mode on your P&IDs (LO, LC, FO, FC, FAI…)

- And much more…

Who Should Attend

- Chemical, Process, Petroleum Engineers

- Design Engineers

- Piping Engineers

- Plant Engineers

- Facility Managers

- Maintenance Technicians

- Mechanics

- Plant Operators

- Recent College Graduates

Target Audiences

- Chemical, Process, Petroleum Engineers

- Design Engineers

- Piping Engineers

- Plant Engineers

- Facility Managers

- Maintenance Technicians

- Mechanics

- Plant Operators

- Recent College Graduates

June 24 course update:

We have added new video lectures. In addition, new quizzes are being added to help you test your knowledge and emphasize the key learning points. The quiz will include:

-

True/False questions

-

Multi-choice questions

-

Images, cross-sectionnal views

-

Solved problems

-

and much more…

When you think you’ve got a good grasp on a topic within the course, you can test your knowledge by taking the quiz. If you pass, wonderful ! If not, you can review the videos and notes again or ask us for help in the Q&A section.

—

September 23 course update:

-

We are implementing:

-

a synchronized high quality english male voiceover

-

revised english subtitles

-

-

Typical valve cross-sectional views and 3D animations are being uploaded to assist in understanding how specific valves work

We are confident that these major updates will undoubtedly take our course to the next level and help you emphasize the key learning points.

—

Dear student,

Valves of various designs and applications are encountered nowadays throughout petroleum refining, petrochemical and process industries as well as in power generation and environmental engineering.

This course is designed to provide you with a complete understanding of construction details and functioning of valves. This understanding is a prerequisite for successful operation of your plant and piping system.

The course includes extensive graphics, 3D animations and cross-sectional viewsto give you a virtual practical exposure on valves.

In this course, you will :

1. Discover the major types of valves used in the process industry

2.Learn their components, their function & their operation

3.Have the opportunity to dismantle many valves and assemble them using 3D models, cross-sectional viewsand 3D animations

4. Also included in this course, an in-depth discussion on actuators and control valves. You will learn how control valves are used to regulate the flow of a fluid. Concepts such as head loss, pressure drop, valve coefficient “Cv”, flow resistance, valve curves and cavitation will be presented.

5. Finally, the course introduces you to valve symbols and representation in engineering drawings such as Piping & Instrumentation Diagrams (P&ID’s). Standards and conventions that apply to valves and their accessories will be discussed in details. You will learn how valve status and failure modes are depicted in engineering drawings.

So with no further ado, check out the free preview videos and the curriculum and we look forward to seeing you in the first section.

Also remember, as enrolled student you will have unlimited access to this material and one-on-one instructor support. So feel free to ask us for help in the Q&A section when needed. It will be our pleasure to help you and make sure you are learning valuable information with us.

Hope to see you there

Cheers,

WR Training

Spread the wings of your knowledge

Course Curriculum

Chapter 1: ABOUT THE COURSE

Lecture 1: Course introduction

Lecture 2: Before you start this course

Chapter 2: VALVES FUNCTIONS AND BASIC PARTS

Lecture 1: Learning objectives

Lecture 2: Introduction

Lecture 3: Valve body

Lecture 4: Valve bonnet

Lecture 5: Valve trim

Lecture 6: Disk and seat

Lecture 7: Stem

Lecture 8: Valve actuator

Lecture 9: Valve packing

Lecture 10: Introduction to the types of valves

Chapter 3: TYPES OF VALVES

Lecture 1: Learning objectives

Lecture 2: Gate valves

Lecture 3: Gate valves : 3D dismantling

Lecture 4: Gate valves : 2D dismantling

Lecture 5: Gate valves : Disk design

Lecture 6: Gate valves : Stem design

Lecture 7: Gate valves : Seat design

Lecture 8: Globe valves

Lecture 9: Globe valves : 3D dismantling

Lecture 10: Globe valves : 2D dismantling

Lecture 11: Globe valves : Z-body design

Lecture 12: Globe valves : Y-body design

Lecture 13: Globe valves : Angle design

Lecture 14: Globe valves : Disk design

Lecture 15: Globe valves : Disk – Stem connections

Lecture 16: Globe valves : Seat design

Lecture 17: Globe valves : Direction of flow

Lecture 18: Ball valves

Lecture 19: Ball valves : Components

Lecture 20: Ball valves : 3D dismantling

Lecture 21: Ball valves : 2D dismantling

Lecture 22: Ball valves : Actuators

Lecture 23: Ball valves : Pros & Cons

Lecture 24: Ball Valves : Port pattern

Lecture 25: Ball valves : Valve materials

Lecture 26: Ball valves : Stem design

Lecture 27: Ball valves : Valve position

Lecture 28: Plug valves

Lecture 29: Plug valves : Valve components

Lecture 30: Plug valves : 3D dismantling

Lecture 31: Plug valves : 2D dismantling

Lecture 32: Plug valves : Numerous designs

Lecture 33: Plug valves : Plug designs

Lecture 34: Plug valves : Multiport plug designs

Lecture 35: Plug valves : Lubricated design

Lecture 36: Plug valves : Non-Lubricated design

Lecture 37: Plug valves : Gland design

Lecture 38: Diaphragm valves

Lecture 39: Diaphragm valves : 3D dismantling

Lecture 40: Diaphragm valves : 2D dismantling

Lecture 41: Diaphragm valves : Straight through & weir types

Lecture 42: Diaphragm valves : Diaphragm construction

Lecture 43: Diaphragm valves : Bonnet design

Lecture 44: Pinch valves

Lecture 45: Pinch valves : Body design

Lecture 46: Butterfly valves

Lecture 47: Butterfly valves : 3D dismantling

Lecture 48: Butterfly valves : Seat design

Lecture 49: Butterfly valves : Disk & Stem assembly

Lecture 50: Needle valves

Lecture 51: Needle valves : 3D dismantling

Lecture 52: Needle valves : Valve applications

Lecture 53: Needle valves : Body design

Lecture 54: Needle valves : Stem packing

Lecture 55: Check valves

Lecture 56: Check valves : Swing

Lecture 57: Swing check valves : 3D dismantling

Lecture 58: Swing check valves : 2D dismantling

Lecture 59: Assembling a swing check valve – 3D model

Lecture 60: Tilting disk check valves

Lecture 61: Lift check valves

Lecture 62: Lift check valves : 3D dismantling

Lecture 63: Lift check valves : 2D dismantling

Lecture 64: Piston check valves

Lecture 65: Butterfly check valves

Lecture 66: Stop check valves

Lecture 67: Relief and Safety valves

Lecture 68: Safety valves

Lecture 69: Safety valves : Pressure setting

Lecture 70: Safety valves : 3D dismantling

Lecture 71: Safety valves : 2D dismantling

Lecture 72: Relief valves

Lecture 73: Relief valves : Valve operation in 2D cross-sectional view

Lecture 74: Relief valves : 3D dismantling

Lecture 75: Relief valves : 2D dismantling

Lecture 76: Control valves

Lecture 77: Control valves : Trim arrangement

Lecture 78: Control valves : Direction of action

Lecture 79: Control valves : 3D dismantling

Lecture 80: Control valves : 2D dismantling

Chapter 4: VALVE ACTUATORS

Lecture 1: Learning objectives

Lecture 2: Introduction

Lecture 3: Manual actuators

Lecture 4: Electric motor actuators

Instructors

-

WR Training

Petroleum Petrochemical & Chemical Engineering

Rating Distribution

- 1 stars: 7 votes

- 2 stars: 12 votes

- 3 stars: 98 votes

- 4 stars: 329 votes

- 5 stars: 470 votes

Frequently Asked Questions

How long do I have access to the course materials?

You can view and review the lecture materials indefinitely, like an on-demand channel.

Can I take my courses with me wherever I go?

Definitely! If you have an internet connection, courses on Udemy are available on any device at any time. If you don’t have an internet connection, some instructors also let their students download course lectures. That’s up to the instructor though, so make sure you get on their good side!

You may also like

- Top 10 Language Learning Courses to Learn in November 2024

- Top 10 Video Editing Courses to Learn in November 2024

- Top 10 Music Production Courses to Learn in November 2024

- Top 10 Animation Courses to Learn in November 2024

- Top 10 Digital Illustration Courses to Learn in November 2024

- Top 10 Renewable Energy Courses to Learn in November 2024

- Top 10 Sustainable Living Courses to Learn in November 2024

- Top 10 Ethical AI Courses to Learn in November 2024

- Top 10 Cybersecurity Fundamentals Courses to Learn in November 2024

- Top 10 Smart Home Technology Courses to Learn in November 2024

- Top 10 Holistic Health Courses to Learn in November 2024

- Top 10 Nutrition And Diet Planning Courses to Learn in November 2024

- Top 10 Yoga Instruction Courses to Learn in November 2024

- Top 10 Stress Management Courses to Learn in November 2024

- Top 10 Mindfulness Meditation Courses to Learn in November 2024

- Top 10 Life Coaching Courses to Learn in November 2024

- Top 10 Career Development Courses to Learn in November 2024

- Top 10 Relationship Building Courses to Learn in November 2024

- Top 10 Parenting Skills Courses to Learn in November 2024

- Top 10 Home Improvement Courses to Learn in November 2024