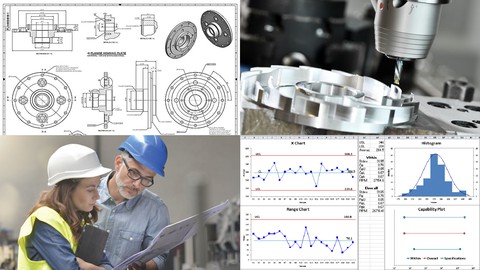

Process Capability Analysis

Process Capability Analysis, available at $84.99, has an average rating of 4.59, with 54 lectures, 5 quizzes, based on 2600 reviews, and has 7988 subscribers.

You will learn about Learn to build histograms and compute the capability statistics in Microsoft Excel Calculate and interpret process capability indices like Cp, Cpk, Pp, Ppk and Cpm. Understand the exact differences between Cpk and Ppk How to apply Process Capability Analysis to manufacturing improvement projects or new parts Interpret the results of a capability study to drive process improvement Advanced topics such as one-sided targets, estimating % defective using capability indices, skew, and kurtosis This course is ideal for individuals who are Quality inspectors, technicians, engineers and managers or Manufacturing professionals or Industrial engineers or Continuous improvement professionals or Six Sigma practitioners It is particularly useful for Quality inspectors, technicians, engineers and managers or Manufacturing professionals or Industrial engineers or Continuous improvement professionals or Six Sigma practitioners.

Enroll now: Process Capability Analysis

Summary

Title: Process Capability Analysis

Price: $84.99

Average Rating: 4.59

Number of Lectures: 54

Number of Quizzes: 5

Number of Published Lectures: 54

Number of Published Quizzes: 5

Number of Curriculum Items: 59

Number of Published Curriculum Objects: 59

Original Price: $39.99

Quality Status: approved

Status: Live

What You Will Learn

- Learn to build histograms and compute the capability statistics in Microsoft Excel

- Calculate and interpret process capability indices like Cp, Cpk, Pp, Ppk and Cpm.

- Understand the exact differences between Cpk and Ppk

- How to apply Process Capability Analysis to manufacturing improvement projects or new parts

- Interpret the results of a capability study to drive process improvement

- Advanced topics such as one-sided targets, estimating % defective using capability indices, skew, and kurtosis

Who Should Attend

- Quality inspectors, technicians, engineers and managers

- Manufacturing professionals

- Industrial engineers

- Continuous improvement professionals

- Six Sigma practitioners

Target Audiences

- Quality inspectors, technicians, engineers and managers

- Manufacturing professionals

- Industrial engineers

- Continuous improvement professionals

- Six Sigma practitioners

Capability analysis is a computational method for comparing the output of a manufacturing process to its engineered specification limits. It’s also an essential set of tools for new process development, 6-sigma projects, Statistical Process Control, and process monitoring. This set of tools can be applied to product characteristics such as its size, weight and hardness, or to process characteristics such as temperature, voltage or flow.

This class, “Process Capability Analysis” starts at the beginning of how manufacturing processes are developed and analyzed. It moves on to the basic concepts of capability analysis along with it applications and math (both “on paper” and in Excel). You will learn how to analyze capability data for a population, for a sample drawn from a population, and from the data found on control charts. At the end, you will also learn more advanced topics such as dealing with one-sided tolerances and an alternate capability index call Cpm. Plus, you’ll receive all the Excel templates and “cheat sheets” you’ll need to apply this to your manufacturing projects.

By the end of this course, you will have a thorough understanding of capability analysis, and be able to apply these tools broadly across a wide range of production problems.

Also, if you are studying for your ASQ CQE, CQT or CQIA exams, this is essential material. I carefully explained the difference between Cpk and Ppk, between analyzing a population and a sample, and how to interpret your capability analysis results; all critical elements on these exams.

Hear what you’re colleagues are saying about Process Capability Analysis:

“This Process Capability Analysis class is awesome!” – Lawrence M.

“Clarity on the confusing Process Capability concepts and how to apply them was well explained. Lecture very good and passionate about the subject. Thank you very much, really enjoyed the course from start to finish.” – Kemsley J.

“I’m a quality manager, consultant and project manager in the food industry. This course was a great way to for me to gain experience with process capability analysis. The explanations were thorough and the examples made the math and statistics come to life. I recommend this to anyone who wants to better understand the measures of process capability.” – Chris F.

“A comprehensive knowledge of utilizing Pp and Cp Indices. Also the instructor have good knowledge and understanding of the topic.” – Nasir M.

“I work in manufacturing and appreciated this courses focus on Cpk and Ppk . it gave me a better understanding of what I was looking at when i analyzed process capability data. it is definitely worth taking if you use process capability charts. Easy to follow and made a dry topic easy to follow and complete!” – Robin S.

“Great course! If you work in a manufacturing environment, you will find that the lessons are very applicable to your everyday dealings with quality. The instructor (Ray) mentions that even many quality professionals are ‘fuzzy’ with some of these concepts. I have found that to be true in my experience. I much appreciate Ray Harkins for delivering this great content!” – Charles S.

“Great refresher course!” – Wallace Y.

If you want to excel as a quality or manufacturing professional, you must understand and be able to apply PROCESS CAPABILITY ANALYSIS. Sign up today!!!

Course Curriculum

Chapter 1: Introduction

Lecture 1: Introduction to "Process Capability Analysis"

Lecture 2: The Manufacturing Development Process, Part 1

Lecture 3: The Manufacturing Development Process, Part 2

Lecture 4: The Manufacturing Development Process., Pt 3

Lecture 5: The Manufacturing Development Process, Pt 4

Lecture 6: Key Process and Product Characteristics

Lecture 7: Measurement Systems, Pt 1

Lecture 8: Measurement Systems, Pt 2

Lecture 9: Sampling Options, Pt 1

Lecture 10: Sampling Options, Pt 2

Lecture 11: A Quick Word about Sampling Size

Lecture 12: The Arithmetic Mean

Lecture 13: Standard Deviation

Lecture 14: Building a Histogram is Excel

Lecture 15: Excel's Data Analysis Add-in

Lecture 16: The Normal Distribution, Pt 1

Lecture 17: The Normal Distribution, Pt 2

Lecture 18: Modality

Lecture 19: Skew

Lecture 20: Kurtosis

Lecture 21: Plotting the Distribution Curve

Lecture 22: Pp and Ppk, Pt 1

Lecture 23: Pp and Ppk, Pt 2

Lecture 24: Pp and Ppk, Pt 3

Lecture 25: Pp and Ppk for Sample Data

Lecture 26: The Run Chart

Lecture 27: Cp and Cpk, Pt 1

Lecture 28: Cp and Cpk, Pt 2

Lecture 29: Interpreting Your Results, Pt 1

Lecture 30: What's the difference between Cpk and Ppk?

Lecture 31: Interpreting Your Results, Pt 3

Lecture 32: Interpreting Your Results, Pt 4, Using DPPM

Lecture 33: An Introduction to Special Topics

Lecture 34: Dealing with One-Sided Tolerances

Lecture 35: Taguchi's Loss Function

Lecture 36: Cpm: Its Math and Application

Lecture 37: More on Cpm

Lecture 38: Using Cpm in the Real World

Lecture 39: Conclusion

Lecture 40: UPDATE: Practical Exercises

Lecture 41: Finding % Out of Tolerance in Excel, Pt 1

Lecture 42: Finding % Out of Tolerance in Excel, Pt 2

Lecture 43: Finding % Out of Tolerance in Excel, Pt 3

Lecture 44: Finding % Out of Tolerance in Excel, Pt 4

Lecture 45: Costing Defects Through A System

Lecture 46: Combining PCA with Quality Costs

Lecture 47: Coefficient of Variation

Lecture 48: SPC versus PCA

Lecture 49: Sturges' Rule

Lecture 50: Z Score

Lecture 51: Applying Z Score

Lecture 52: Norm Functions in Excel

Lecture 53: Calculating Equivalent Cpk

Lecture 54: Bonus Lecture

Instructors

-

Ray Harkins, The Manufacturing Academy

Senior Manufacturing Professional, Online Educator

Rating Distribution

- 1 stars: 7 votes

- 2 stars: 22 votes

- 3 stars: 194 votes

- 4 stars: 915 votes

- 5 stars: 1462 votes

Frequently Asked Questions

How long do I have access to the course materials?

You can view and review the lecture materials indefinitely, like an on-demand channel.

Can I take my courses with me wherever I go?

Definitely! If you have an internet connection, courses on Udemy are available on any device at any time. If you don’t have an internet connection, some instructors also let their students download course lectures. That’s up to the instructor though, so make sure you get on their good side!

You may also like

- Best Video Editing Courses to Learn in February 2025

- Best Music Production Courses to Learn in February 2025

- Best Animation Courses to Learn in February 2025

- Best Digital Illustration Courses to Learn in February 2025

- Best Renewable Energy Courses to Learn in February 2025

- Best Sustainable Living Courses to Learn in February 2025

- Best Ethical AI Courses to Learn in February 2025

- Best Cybersecurity Fundamentals Courses to Learn in February 2025

- Best Smart Home Technology Courses to Learn in February 2025

- Best Holistic Health Courses to Learn in February 2025

- Best Nutrition And Diet Planning Courses to Learn in February 2025

- Best Yoga Instruction Courses to Learn in February 2025

- Best Stress Management Courses to Learn in February 2025

- Best Mindfulness Meditation Courses to Learn in February 2025

- Best Life Coaching Courses to Learn in February 2025

- Best Career Development Courses to Learn in February 2025

- Best Relationship Building Courses to Learn in February 2025

- Best Parenting Skills Courses to Learn in February 2025

- Best Home Improvement Courses to Learn in February 2025

- Best Gardening Courses to Learn in February 2025