Tolerance Stack Ups for Mechanical engineers with Six-Sigma

Tolerance Stack Ups for Mechanical engineers with Six-Sigma, available at $44.99, has an average rating of 4.29, with 41 lectures, based on 88 reviews, and has 621 subscribers.

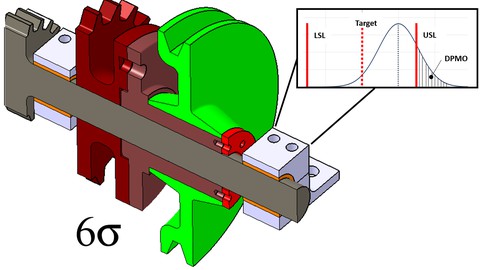

You will learn about Worst-Case approach Statistical approach (RSS) Six-Sigma approach Create the loop for tolerance analysis in 2D Estimate the quality level of the assembly Estimate the expected Defects Per Million of Opportunities (DPMO) Inflation factors for non-normal distributions (Ci) Process capablity index (Cp) from manufacturing Dynamic shift (k) for loss of performance over time Understand trade-offs for tolerance analysis Customer requirements (LSL, USL) This course is ideal for individuals who are Mechanical designers (entry level) or Mechanical engineers or Students of mechanical engineering It is particularly useful for Mechanical designers (entry level) or Mechanical engineers or Students of mechanical engineering.

Enroll now: Tolerance Stack Ups for Mechanical engineers with Six-Sigma

Summary

Title: Tolerance Stack Ups for Mechanical engineers with Six-Sigma

Price: $44.99

Average Rating: 4.29

Number of Lectures: 41

Number of Published Lectures: 41

Number of Curriculum Items: 46

Number of Published Curriculum Objects: 46

Original Price: $54.99

Quality Status: approved

Status: Live

What You Will Learn

- Worst-Case approach

- Statistical approach (RSS)

- Six-Sigma approach

- Create the loop for tolerance analysis in 2D

- Estimate the quality level of the assembly

- Estimate the expected Defects Per Million of Opportunities (DPMO)

- Inflation factors for non-normal distributions (Ci)

- Process capablity index (Cp) from manufacturing

- Dynamic shift (k) for loss of performance over time

- Understand trade-offs for tolerance analysis

- Customer requirements (LSL, USL)

Who Should Attend

- Mechanical designers (entry level)

- Mechanical engineers

- Students of mechanical engineering

Target Audiences

- Mechanical designers (entry level)

- Mechanical engineers

- Students of mechanical engineering

Stack up and Tolerance Design is all about quality, or in other words, the allowable parts to be rejected during the process. In escence, this results in an iterative process between the design department, manufacturing and the customer. In this course you will learn the concepts to master plus/minus tolerance stack ups in 2D. At then end, you will become a valuable member for your company because you will be capable to assess assemblies and propose changes to meet critical requirements. Although currently there are several software which run complex tolerance analysis in 3D, in my experience, most of the times you can simplify the problem with a 2D analysis, so as mechanical designer YOU MUST be capable of performing 2D analysis in order to save valuable resources to the company.

First, you will learn the basics: The definition of nominal value, tolerance, standard deviation, normal distribution and the importance of tolerance analysis in mechanical design.

Then. you will learn how to create the sketch (loop) to follow in the calculation of tolerance analysis. Several exercises will be provided so you can practice this process.

Next you will Learn how to perform a linear stack ups with three approaches:

-

Worst Case: When no rejections are allowed. This apporach results in the most expensive, but it is used in critical applications.

-

Statistical: Some rejections are allowed. The costs are reduced because some defects will always be presented.

-

Six-Sigma: Complex considerations such as process distributions, process caapability and loss of performance are taken into account to improve the design at different quality levels.

Finally, for each approach I will provide you five assemblies with different requirements. You will need to apply the concepts to find the suitable design which meet the quality levels and solve the critical clearances. A template in excel will allow you to perform these calculations.

Please note:We will cover ONLY plus/minus tolerances. But the knowledge is also applicable for geometric tolerances.

This course is based in my own experience as designer in the aerospace industry for 10 years. I used this methods everyday to discuss initial changes with customer, find a suitable provider and reduce costs with manufacturing.

Course Curriculum

Chapter 1: Introducción

Lecture 1: Intro

Lecture 2: What is tolerance analysis (Stack up)?

Lecture 3: Fundamentals & definitions

Lecture 4: Standard deviation

Lecture 5: Dimensioning methods

Lecture 6: Steps to perform a tolerance analysis

Lecture 7: Example of sketch creation

Chapter 2: Sketch creation

Lecture 1: Instructions for the following homeworks

Chapter 3: Worse-Case approach (WC)

Lecture 1: What is the Worst-Case approach?

Lecture 2: Mathematical definition of WC

Lecture 3: Example WC

Lecture 4: Template in excel for WC

Lecture 5: Practice problems WC (watch before the following videos)

Lecture 6: Solution: Assembly I

Lecture 7: Solution: Assembly II

Lecture 8: Solution: Assembly III

Lecture 9: Solution: Assembly IV

Lecture 10: Solution: Assembly V

Chapter 4: Root Sum Square approach (RSS)

Lecture 1: What is RSS approach?

Lecture 2: Mathematical definition of RSS

Lecture 3: Example RSS

Lecture 4: Template in Excel for RSS

Lecture 5: Practice problems RSS (watch before the following videos)

Lecture 6: Solution: Assembly I

Lecture 7: Solution: Assembly III

Lecture 8: Solution: Assembly IV

Lecture 9: Solution: Assembly V

Chapter 5: Six-Sigma approach

Lecture 1: What is Six-Sigma approach?

Lecture 2: Mathematical definition for mixed distributions

Lecture 3: Example using mixed distributions

Lecture 4: Mathematical definition for process capability

Lecture 5: Example using process capability

Lecture 6: Mathematical definition for dynamic shift

Lecture 7: Example using dynamic shif

Lecture 8: General equation for tolerance analysis

Lecture 9: Template in Excel for Six-Sigma approach

Lecture 10: Practice problems Six-Sigma (watch before the following videos)

Lecture 11: Solution: Assembly I

Lecture 12: Solution: Assembly III

Lecture 13: Solution: Assembly IV

Lecture 14: Solution: Assembly V

Instructors

-

Santiago Aguillón

MSc in Aircraft Design, Stock Investor & Trader

Rating Distribution

- 1 stars: 2 votes

- 2 stars: 2 votes

- 3 stars: 15 votes

- 4 stars: 32 votes

- 5 stars: 37 votes

Frequently Asked Questions

How long do I have access to the course materials?

You can view and review the lecture materials indefinitely, like an on-demand channel.

Can I take my courses with me wherever I go?

Definitely! If you have an internet connection, courses on Udemy are available on any device at any time. If you don’t have an internet connection, some instructors also let their students download course lectures. That’s up to the instructor though, so make sure you get on their good side!

You may also like

- Best Video Editing Courses to Learn in March 2025

- Best Music Production Courses to Learn in March 2025

- Best Animation Courses to Learn in March 2025

- Best Digital Illustration Courses to Learn in March 2025

- Best Renewable Energy Courses to Learn in March 2025

- Best Sustainable Living Courses to Learn in March 2025

- Best Ethical AI Courses to Learn in March 2025

- Best Cybersecurity Fundamentals Courses to Learn in March 2025

- Best Smart Home Technology Courses to Learn in March 2025

- Best Holistic Health Courses to Learn in March 2025

- Best Nutrition And Diet Planning Courses to Learn in March 2025

- Best Yoga Instruction Courses to Learn in March 2025

- Best Stress Management Courses to Learn in March 2025

- Best Mindfulness Meditation Courses to Learn in March 2025

- Best Life Coaching Courses to Learn in March 2025

- Best Career Development Courses to Learn in March 2025

- Best Relationship Building Courses to Learn in March 2025

- Best Parenting Skills Courses to Learn in March 2025

- Best Home Improvement Courses to Learn in March 2025

- Best Gardening Courses to Learn in March 2025